N-Terpinal NT-DeScaler is a synthetic acid with surfactant base green chemical agent for the safe removal of rust and scale from ferrous and non-ferrous metals, concrete, and other substrates. N-Terpinal NT-DeScaler is a highly concentrated chemical emulsion, designed to replace corrosive acids and flammable compounds. It is environmentally safe, containing the newest research in chemical technology and proven one of the most aggressive aqueous descalers. It is also a great product for the removal of ash and scale from a burn-off oven processes. Instructions: NT-DeScaler is a stable chemical formulation which is designed for a safe acid cleaning process. The product can be sprayed on, or parts can be soaked to remove the contamination. Flash rust and light scale can be removed on contact, while heavy rust and scale may be soaked for several hours or over night. The NT-DeScaler will clean and etch concrete to prep for concrete coating systems.Scale is the accumulation of minerals such as calcium and magnesium on the waterside of boiler heating surfaces. When boiler water turns to steam, residual minerals are left in the boiler. These minerals then settle out of the boiler water and form scale on the boiler heating surfaces.Unlike the harsh chemicals you’ve used in the past, NT-Degreaser is a safe, quick, and easy solution.

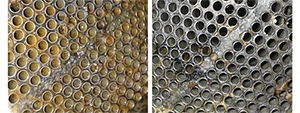

NT-Degreaser is used for stainless steel, and it is safe on steel, iron, copper, plastic, and rubber. With NT-Degreaser, iron oxide deposits and calcium carbonate deposits are guaranteed to dissolve. Chemical descalers can handle various industrial descaler applications, such as boilers, hot water tanks, steam generators, plate, and shell heat exchangers, condensers, chillers, cooling coils, oil coolers, and more.Water-formed deposits, such as limescale, can rob equipment of much of its efficiency, increase operating costs, and shorten equipment life. A chemical descaler is an easy and effective way to remove deposits like scale, limescale, and rust. Chemical descalers act on calcium carbonate, sulfate, and silica buildup to break them down and flush them from the system.

Chemical scale removal can be accomplished in several ways, but it is most effective when the chemical is pumped through the piping and connections of a system. WSI INDUSTRIES, LLC. provides NT-Degreaser biodegradable liquid descaler products that safely dissolve all water scale, lime, rust and other water-formed deposits. With our individualized approach, we help you restore equipment and systems efficiently, economically and safely. Whether you are looking to lower head pressures, reduce power consumption, extend equipment life or increase water flow and function, our eco-friendly and safe-to-handle NT-Descaler can be customized for your commercial cleaning application.Understanding the cleaning effectiveness or scale dissolvability of NT-Descaler during cleaning is an important part of your procedural steps. This simple practice is designed to make sure your solutions activity level retains functionality. Performing these tests can be accommodated in two straightforward methods, measuring the pH value of your circulating solution and mapping the readings or a simple calcium carbonate spot test of the circulating solution.

Testing the pH of your NT-Descale solution during circulation is one method that will identify NT-Descaler activity level. The pH of NT-Descaler starts out with a value of less than 3. As NT-Descaler dissolves the deposits within your equipment, it absorbs the calcium into a liquid suspension, thus naturally neutralizing the solution. Frequent pH readings at intervals of every 10-15 minutes will allow you to map your solution’s activity during a cleaning procedure.

Example: if you have been testing your pH with a consistent pH reading below 3 and the solution abruptly rises, take additional readings to make sure this is a consistent pattern. If your pH has a consistent 5.5 reading or greater for multiple readings, your solution has become neutralized and you will need to add an additional product to complete your cleaning. If you have circulated for the recommended time duration, the pH did not go above 4 and you are not visually seeing any additional bubbling & foaming, your cleaning is complete. You can now start flushing your piece of equipment with clean water.

A calcium carbonate spot test is performed by simply having a sample of your NT-Descaler solution come in contact with a form of calcium carbonate. The calcium carbonate utilized can be a sample of the deposit you are cleaning, a calcium tablet, or concrete. When you add the calcium to your NT-Descaler solution, if the product is active, it will bubble and foam. If you add the calcium tablet and visualize a little reaction, your solution is neutralized. You can perform this test with fresh NT-Descaler so you understand how the fresh products will react vs depleted. If your NT-Descale solution has lost its effectiveness, you will need to add fresh ScaleBreak to complete the cleaning. If your NT-Descale remained active during the recommended cleaning duration, you can perform a clean water flush.