The NT-Degreaser is a heavy duty degreaser designed to cut film, oil, and grease from industrial parts, chassis, painted surfaces, and is an exceptional general purpose floor cleaner. This degreaser is safer than most other corrosive degreasers, NT-Degreaser is biodegradable and does not contain petroleum solvents. NT-Degreaser are chemical substances that dissolve water-insoluble substances (greases, dirt and oils) from hard surfaces. They are generally used as a degreasing agent for removing substances from machines, floors, tools and hard surfaces. The NT-Degreaser is used to remove grease, grime, oil and other oil-based contaminants from a variety of substrates including automotive or miscellaneous metallic parts. A degreaser is generally required in areas that need heavy duty cleaning such as restaurants. Heavy duty degreasers are manufactured from hydrocarbon solvents such as kerosene and xylene.

A degreaser has the following benefits for users:

Completely removes insoluble substances.

An eco-friendly cleaner.

Less hazardous to humans.

Non-corrosive and non-conductive.

Application of NT-Degreaser

NT-Degreaser is not solvent-based or solvent-containing substances, and may contain surfactants as active ingredients. The solvents used in degreasers have a dissolving action on grease and similar water-insoluble substances. An alkaline washing agent is added to the solvent-containing NT-Degreaser to enhance its degreasing ability. NT-Degreaser can also be produced as solvent-free, based on alkaline chemicals and/or surfactants.

The task of industrial cleaning and degreasing covers a wide range of applications across almost every conceivable industry, particularly in wash bays for heavy vehicles, trains, and aircraft. Regular cleaning is a vital part of most industrial maintenance regimes and it’s not just about maintaining appearances. Keeping equipment, vehicles and work spaces clean is an integral part of looking after critical infrastructure as well as maintaining a safe and healthy working environment.

Put simply “soiling” is any unwanted substance that covers an object. Whilst that could mean almost anything, it is possible to break soils down into two categories:

Organic soiling is anything derived from living material (including fossils fuels) such as oil, petroleum products, grease, fats, proteins and living matter.

Inorganic soiling typically includes matter such as scale, minerals, clay, dirt and rust.

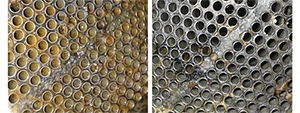

Most industrial cleaning tasks require the removal of mixed soils, which is a combination of both organic and inorganic materials. In these situations organic contaminants such as oil and grease build up on equipment where they bond with dust, dirt and other matter.

For this reason industrial cleaning has a high focus on degreasing and the lifting of oils from surfaces, along with the contaminants they trap. Most industrial cleaning tasks are, therefore, best defined as industrial degreasing tasks.

Traditional Industrial Degreasers

Traditional industrial degreasers are based on a combination of ingredients that are combined in varying degrees to obtain the desired cleaning / degreasing effect. Some of these ingredients can cause significant unwanted side-effects such as damage to equipment or contamination of waste-water.

The NT-Degreaser ingredients include:

Builders

Inhibitors

Chelating Agents

Sequestering Agents

Saponifiers

Emulsifiers

Strong Alkalies

Petroleum Products

NT-Degreaser remove oils and other soils through aggressive chemical reactions. Whilst these reactions can be effective at degreasing surfaces, they can also just as easily damage the surface being cleaned. They can also pose burn risks to workers and can harm the environment.

NT-Degreaser does not contain toxic and environmentally damaging surfactants and/or solvents, which can cause harm to people and the environment. Butyl Cellosolve, for example, is a primary ingredient in many popular degreasers today; however, it is well known to be very harmful to humans. There are many other toxic solvents hidden within degreasers in common use today.

Problems with Traditional Degreasers

One of the greatest issues with traditional degreasers is emulsification. Emulsifiers remove oil from surfaces and hold them within the water mixture for long periods of time. Whilst this can be an effective way to degrease, it leaves behind a large volume of highly contaminated waste water which cannot be disposed of safely without expensive processing.

The waste water produced by emulsifying degreasers contains high concentrations of toxic hydrocarbons. Because these hydrocarbons are so effectively mixed with water, they become highly “bio-available” meaning they are easily ingested by plant and animals – particularly marine life.

What are the Regulations of NT-Degreaser

There are strict regulations in most countries on the levels of hydrocarbon allowed in waste water. In almost all cases, an emulsifying degreaser will produce waste water that does not fall within these regulations.

New, Safe Technology in Industrial NT-Degreaser

Developments in chemical technology have led to the development of industrial degreasers that overcome the problems associated with traditional products.

New and more effective degreasers are now available which are derived from plant-based materials rather than petrochemicals. Advances in surfactant technology have also done away with the need for many of the problematic ingredients found in degreasers, which can affect waste water quality and place the environment at risk.

Aside from the environmental impact, the right choice of degreaser can have a massive and direct impact on the costs of waste water processing.

New NT-Degreaser heavy-duty industrial degreaser is now available which are actually more effective than the toxic, dangerous product they replace. Non-toxic, quick break degreasers that lift oil-based soils without causing an emulsion are the leading solution to safe, eco-friendly industrial degreasing.

Derived from natural ingredients, the NT-Degreaser safe for workers, eco-friendly and lead to better waste water quality by enabling full separation of oil and other hydrocarbons in oil water separators.Industrial degreasing solvents are a solution that is used to prepare or ready a part or metal object for further or additional operations, such as painting or electroplating. The solvent is made up of a particular chemical solution, which could include multiple chemicals to make up a certain degreasing concoction, in order to dissolve machining fluids and contaminants that could be lingering on the part or metal object.

NT-Degreaser should be applied directly on the surface either by wiping, brushing or spraying. If done correctly, and if a strong enough industrial degreasing solvent was used, the entire process should have removed any dirt, oil, grease, loose particles, and any other contaminants that might still exist or have stained the surface of the material or object.

An additional step that people and companies use to clean a metal or whatever material it is that needs cleaning is through immersion. Immersing the object into a tank of some sort, with the contents of the industrial degreasing solvent and agitating it (similar to how a washing machine works) is an effective method to removing particles and contaminants from the piece.

What are the Benefits of NT-Degreaser

The benefits to using NT-Degreaser versus other types of cleaning agents, especially vapor degreasing solutions, include:

The reduction of emissions when compared to vapor degreasing operations

Not nearly as much venting is required, which means it is much easier to rapidly set up and put in place a small degreasing operation

Liquid solvents are simply easier to deal with than vapor degreasing agents

To learn more about industrial degreasing solvents and how their use can benefit you or your company, get in touch with WSI INDUSTRIES, LLC sooner rather than later. WSI INDUSTRIES, LLC is an established company that can provide a plethora of knowledge and information as it pertains to industrial degreasing solvents, which will subsequently help you make the right decision based on what operation you are performing on your materials.